BC:Ntensify®—promising process intensification solutions—increases capacity, reduces energy and chemical use, and helps meet stringent nutrient limits.

BC:Ntensify®—promising process intensification solutions—increases capacity, reduces energy and chemical use, and helps meet stringent nutrient limits.

Process Densification with BC:Ntensify®

Fewer resources. Better results.

The water industry is working to improve water quality, increase capacity, and meet stringent nutrient limits, while balancing the significant capital investment of ongoing operational costs and other competing demands like aging infrastructure and climate change. Utilities that are adopting innovative process intensification technologies are optimizing their wastewater treatment plant to do more with less. BC:Ntensify® is a suite of process intensification solutions that are helping facilities to sustainably meet existing and future nutrient regulations, save costs, and reduce their environmental impact.

Process Densification with BC:Ntensify®

Fewer resources. Better results.

The water industry is working to improve water quality, increase capacity, and meet stringent nutrient limits, while balancing the significant capital investment of ongoing operational costs and other competing demands like aging infrastructure and climate change. Utilities that are adopting innovative process intensification technologies are optimizing their wastewater treatment plant to do more with less. BC:Ntensify® is a suite of process intensification technologies that are helping facilities to sustainably meet existing and future nutrient regulations, save costs, and reduce their environmental impact.

BC:Ntensify® is an affordable and highly scalable suite of proven process intensification solutions that can often be deployed within existing infrastructure to increase capacity, improve effluent quality, provide chemical and energy savings, and support resource recovery.

BC:Ntensify® is an affordable and highly scalable suite of proven process intensification solutions that can often be deployed within existing infrastructure to increase capacity, improve effluent quality, provide chemical and energy savings, and support resource recovery.

BC:Ntensify® results in:

1. Increased Capacity: Improved process capacity by intensifying the biological process, reducing the footprint of a treatment plant, and pushing more flow and load through the facility without exceeding plant capacity limitations.

2. Improved Effluent Quality: When we intensify the biological process, we can maximize capacity and improve the effluent requirements.

3. Chemical Savings: When improving effluent requirements, we do it with very little dependency on chemicals. Process intensification requires the least chemicals possible, although some stringent nutrient requirements we may require some chemicals, but less dependency is crucial.

4. Energy Savings: One of the highest ticket items when it comes to operations and maintenance to run a WWTP is energy costs. BC:Ntensify® designs biological and treatment processes to minimize the energy used, to be energy neutral, or energy positive in the future.

5. Resource Recovery: Not all facilities are set up for resource recovery, but we strive to recover resources when we’re able and as needed.

BC:Ntensify® is a process densification technology that results in:

1. Increased Capacity: Improved process capacity by intensifying the biological process, reducing the footprint of a treatment plant, and pushing more flow and load through the facility without exceeding plant capacity limitations.

2. Improved Effluent Quality: When we intensify the biological process, we can maximize capacity and improve the effluent requirements.

3. Chemical Savings: When improving effluent requirements, we do it with very little dependency on chemicals. Process intensification requires the least chemicals possible, although some stringent nutrient requirements we may require some chemicals, but less dependency is crucial.

4. Energy Savings: One of the highest ticket items when it comes to operations and maintenance to run a WWTP is energy costs. BC:Ntensify® designs biological and treatment processes to minimize the energy used, to be energy neutral, or energy positive in the future.

5. Resource Recovery: Not all facilities are set up for resource recovery, but we strive to recover resources when we’re able and as needed.

Process Densification with BC:Ntensify®

BC:Ntensify® is a suite of process intensification solutions that are helping facilities to sustainably meet existing and future nutrient regulations, save costs, and reduce their environmental impact. One BC:Ntensify® solution has combined process intensification using simultaneous nitrification and denitrification (SND) coupled with advanced aeration and selectors, including inDENSE™ hydrocyclones. Hydrocyclone-based wasting yields long-term benefits for treatment performance and operational improvements. The ease of installation, operation, and maintenance compared to alternative solutions makes BC:Ntensify® especially attractive to wastewater treatment facilities. Aeration is the most energy-intensive operation in wastewater treatment—and accounts for an estimated 45-75% of plant energy costs. With BC:Ntensify® advanced aeration controls, facilities can realize benefits of SND lowering oxygen use and improving treatment efficiency. The treatment process can be simplified by reducing or eliminating internal mixed liquor recycles and intensifying biochemical reactions, which reduces facility energy and chemical use.

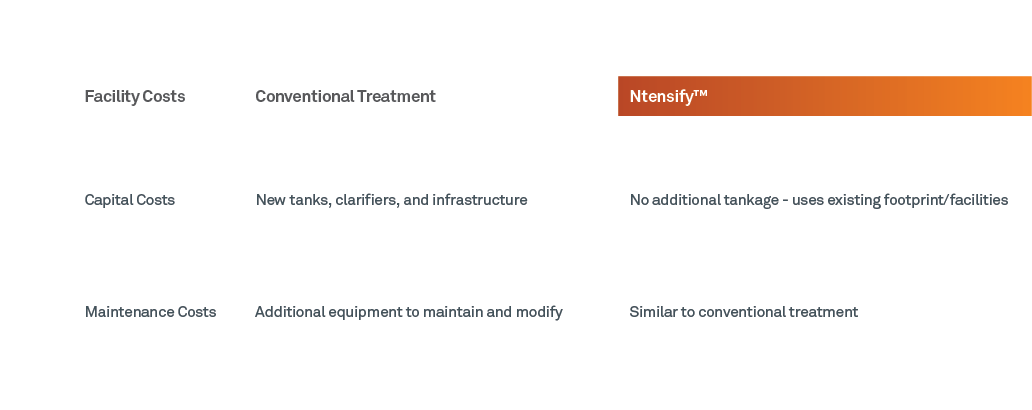

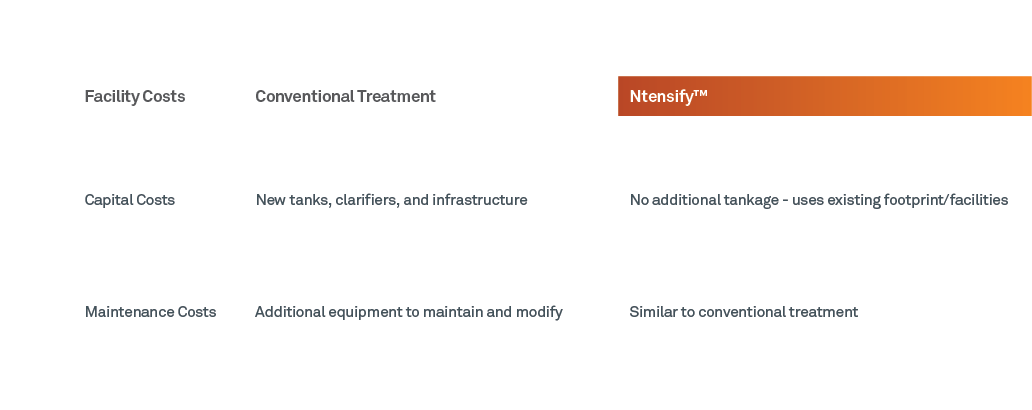

Implementation

Leveraging BC:Ntensify® can help utilities to improve biological nutrient removal and prepare for more stringent nutrient regulations, while using fewer resources and at a lower operating cost than traditional approaches. Our work with a medium-sized (15-20 mgd) facility in Pueblo, Colorado that implemented BC:Ntensify® soutions achieved a 50% increase in capacity, a $150K/year in energy savings, $300k/year in chemical savings, and also helped to gain credits to extend their compliance schedule for low-level nutrient limits.

Pueblo, Colorado

Purpose: to improve nitrogen and phosphorus removal while minimizing the use of supplemental carbon and aeration energy.

Implementation

Leveraging BC:Ntensify® can help utilities to improve biological nutrient removal and prepare for more stringent nutrient regulations, while using fewer resources and at a lower operating cost than traditional approaches. Our work with a medium-sized (15-20 mgd) facility in Pueblo, Colorado that implemented BC:Ntensify® solutions achieved a 50% increase in capacity, a $150K/year in energy savings, $300k/year in chemical savings, and also helped to gain credits to extend their compliance schedule for low-level nutrient limits.

Pueblo, Colorado

Purpose: to improve nitrogen and phosphorus removal while minimizing the use of supplemental carbon and aeration energy.

Do you need help planning to meet future nutrient limit regulations within a constrained budget and facility footprint?

Are you concerned about the long-term operation and maintenance of implementing new biological nutrient removal technologies?

By leveraging innovative solutions like BC:Ntensify®, Brown and Caldwell is helping clients treat more water, get the most out of their existing facility footprints, and meet future nutrient limits, and do more with less.

Related News

- Rocky Mountain Water Conference

- WEFTEC 2024

- Brown and Caldwell welcomes national specialty leader of reuse regulations and policy

- AWWA ACE24

- WEFTEC 2023

- Peracetic Acid: A Tool for Wastewater Disinfection Compliance

- AWWA ACE23

- Research project underway to prepare water utilities for wildfire events

- Researchers are calling this wastewater treatment process intensification and optimization solution ‘powerful’ and ‘elegant’

- Advanced analytics minimizes data waste in wastewater utilities

Awards

-

2020

Water Environment Federation, Project Excellence Award, James R. DiIorio Water Reclamation Facility Ntensify® Nutrient Removal