Comprehensive treatability testing

Over the last 20 years, Brown and Caldwell’s treatability testing laboratory has provided U.S. and international clients with the latest tools and technologies to perform comprehensive treatability testing with the goal of optimizing solutions for wastewater, drinking, reclaimed, and industrial waters. Reliable laboratory results increase client confidence and facilitate informed decision-making with the potential to reduce the cost and risk of facility design, construction, and operation.

Whether providing technical evaluations to existing systems or developing new treatment processes, our experts will guide you through potential testing approaches to deliver practical and cost-effective results.

Comprehensive treatability testing

Over the last 20 years, Brown and Caldwell’s treatability testing laboratory has provided U.S. and international clients with the latest tools and technologies to perform comprehensive treatability testing with the goal of optimizing solutions for wastewater, drinking, reclaimed, and industrial waters. Reliable laboratory results increase client confidence and facilitate informed decision-making with the potential to reduce the cost and risk of facility design, construction, and operation.

Whether providing technical evaluations to existing systems or developing new treatment processes, our experts will guide you through potential testing approaches to deliver practical and cost-effective results.

A disciplined approach, grounded in science

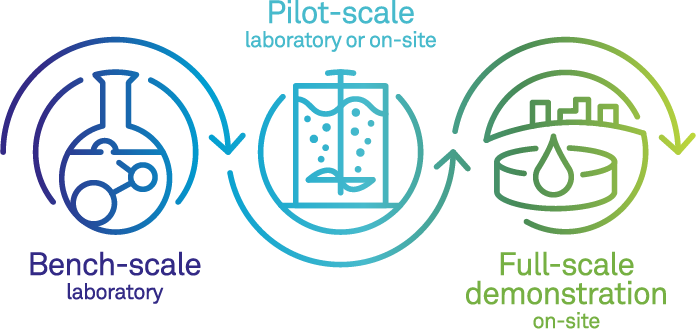

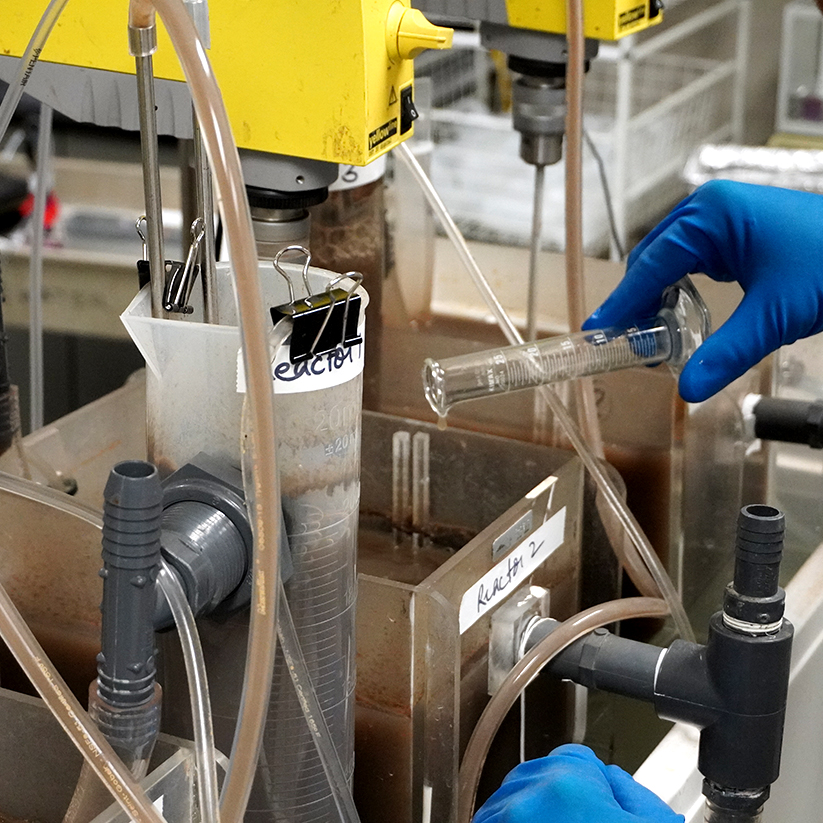

Our laboratory specializes in bench- and small pilot-scale testing and confirms outcomes at higher flows using facilities on project sites. Our trained team of laboratory engineers and scientists collaborates with design teams to accurately gather and test data that reflects on-site treatment conditions to inform and confirm potential solutions that optimize treatment design, implementation, and process operations.

A disciplined approach, grounded in science

Our laboratory specializes in bench- and small pilot-scale testing and confirms outcomes at higher flows using facilities on project sites. Our trained team of laboratory engineers and scientists collaborates with design teams to accurately gather and test data that reflects on-site treatment conditions to inform and confirm potential solutions that optimize treatment design, implementation, and process operations.

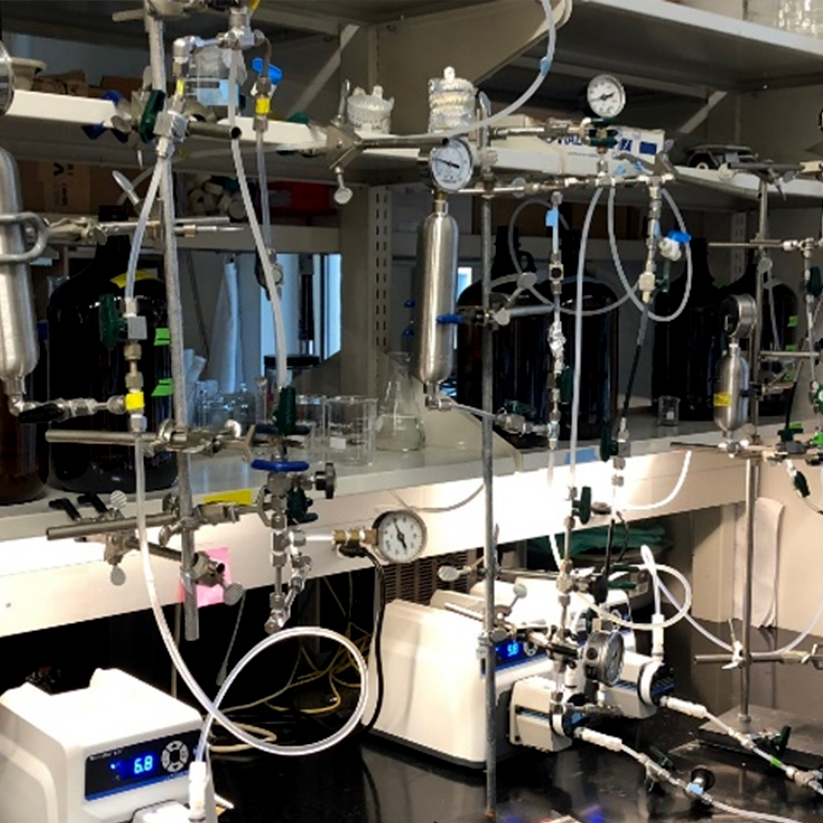

Optimizing solutions inside our Treatability Testing Laboratory

BC’s Treatability Testing Laboratory optimizes client solutions for wastewater, drinking, reclaimed, and industrial waters. Our breakthrough solutions have saved clients millions in capital costs and reduced the risks of facility design, construction, and operation.

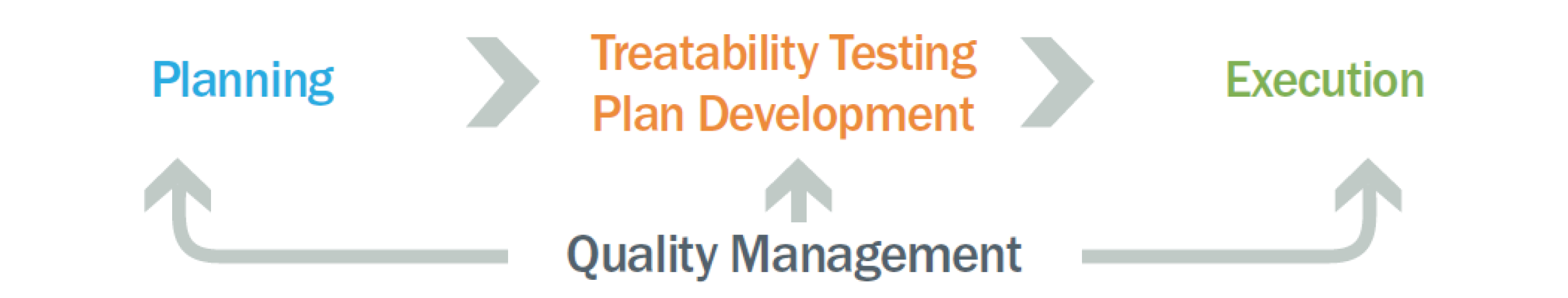

Delivering quality treatability testing data

Delivering quality treatability testing data

Identifying and proving solutions for PFAS

BC provides services for the testing and development of treatment solutions for PFAS and other emerging contaminants. We develop design criteria for engineering traditional treatment solutions and are working with innovative technology partners to bring to market new proven solutions and technologies.

Ntensify Enhanced Nutrient Removal

$32 million in capital cost savings

Ntensify Enhanced Nutrient Removal

$32 million in capital cost savings

Water Treatment Plant Granular Activated Carbon Testing

$4.5 Million in construction cost savings

Water Treatment Plant Granular Activated Carbon Testing

$4.5 Million in construction cost savings

Chemical Plant Startup Effluent Compliance

$90,000 in commercial bacteria savings

Chemical Plant Startup Effluent Compliance

$90,000 in commercial bacteria savings

“Every treatability project brings unique challenges and results, which ultimately contributes to solving a small piece of the water and wastewater treatment puzzle around the world.”

Ali Teymouri

Laboratory Research Manager

“Every treatability project brings unique challenges and results, which ultimately contributes to solving a small piece of the water and wastewater treatment puzzle around the world.”

Ali Teymouri

Laboratory Research Manager