Methane is a colorless, odorless gas — and a potent greenhouse gas (GHG). While methane emissions, or fugitive methane, are commonly associated with the oil and gas sector, water resource recovery facilities (WRRFs) are another common — and often overlooked — source.

This represents an opportunity for sustainability and bioenergy programs, if handled safely and correctly.

Impacts of fugitive methane at WRRFs

Sustainability is one area where fugitive methane can make an impact. Other influences can reach various aspects of facility operations and performance, including:

- Safety. Unidentified biogas leaks can be hazardous.

- Revenue and costs. Leaks result in revenue and resource losses for bioenergy programs selling to the grid or are additional costs for programs aiming to offset onsite energy use.

- Climate. Identifying and quantifying fugitive methane helps WRRFs develop mitigation strategies that will allow them to substantially move towards meeting climate action plans and GHG reduction goals.

- Odors. Fugitive emissions cause odors that can negatively impact the community. Addressing these emissions can help to reduce odors, improving community stewardship.

- Public perception and community trust. Awareness of fugitive emissions enables utilities to be transparent and address them before they escalate into public concerns.

- GHG mitigation grants. More funding is becoming available for utilities to engage in GHG-reduction projects. Understanding your emissions profile and feasible targets for reduction strategies can improve eligibility and success in securing funding.

Identification and mitigation

Fugitive methane can be reduced with straightforward solutions such as repairing PRVs, tightening valves, or replacing gaskets. More complex solutions include replacing floating covers with fixed covers or advanced air treatment. However, the first step is identifying the source.

The City of Columbus Southerly Wastewater Treatment Plant is seen from an aerial view using an OGI camera and flame ionization detector.

Known significant contributors of fugitive methane at WRRFs are:

- Floating digester covers

- Odor control systems associated with biosolids storage

- Solids dewatering and conveyance

- Dewatered cake storage

- Digester pressure relief valves (PRVs) and other appurtenances

- Biogas handling equipment

Brown and Caldwell (BC) has established a tiered multi-sensor approach for GHG emissions measurement that is based on a WRRF’s site-specific needs:

- Tier 1: Conduct a facility-wide desktop data analysis

- Tier 2: Identify process-specific emissions with an optical gas imaging (OGI) camera and other ground measurement tools

- Tier 3: Quantify facility-wide emissions with drone flux method (DFM) technology.

Together, these services offer facilities a comprehensive understanding of their fugitive methane sources — and help create a baseline so that mitigation solutions can be implemented.

Case study: Tracking down the fugitive

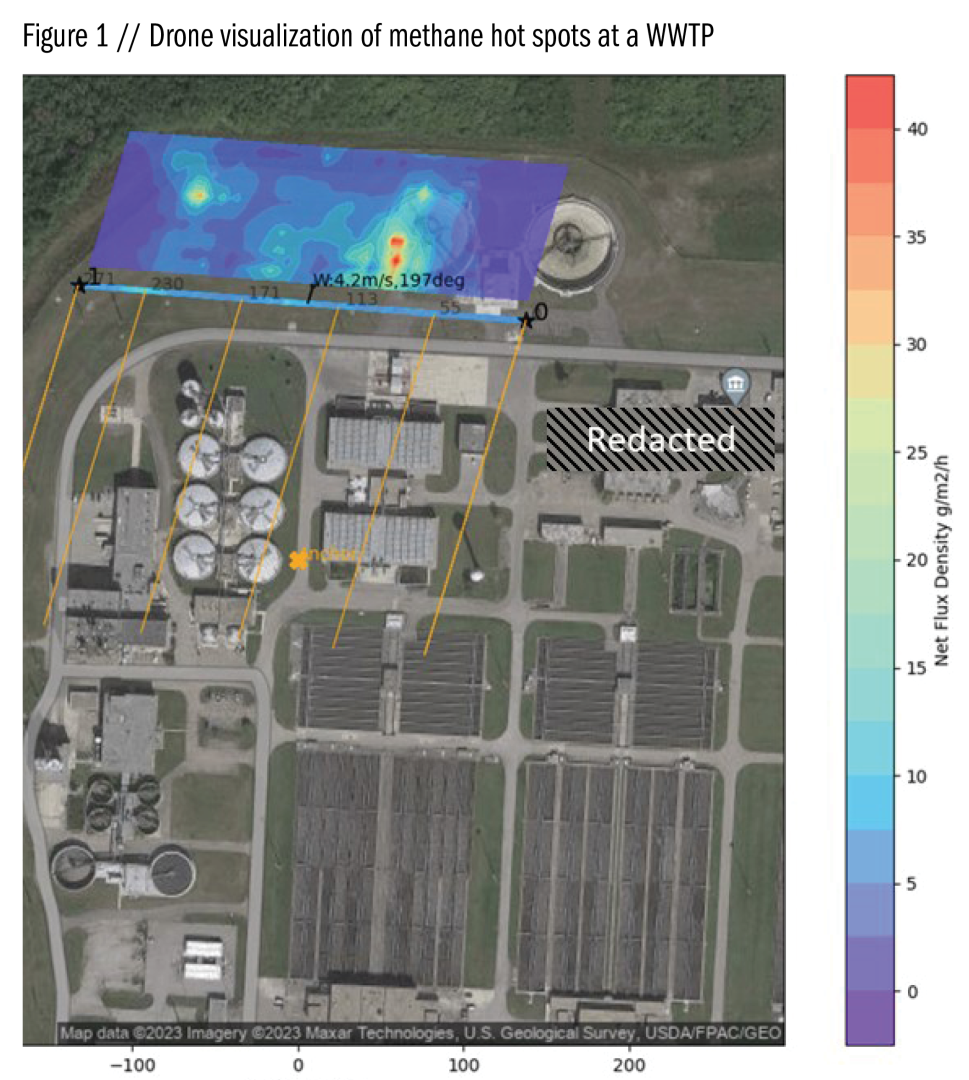

BC conducted a top-down, bottom-up fugitive methane campaign at the City of Columbus Southerly Wastewater Treatment Plant (WWTP) focusing on the solids handling and treatment system. The team identified process and component specific emissions with an OGI camera and flame ionization detector and quantified facility-wide emissions with DFM technology.

The survey campaign found that the Southerly WWTP was losing at least 15% of its total biogas production. The Southerly WWTP is planning on implementing a bioenergy project that includes co-digestion and beneficial use of the biogas through combined heat and power (CHP).

The fugitive methane emissions would reduce the GHG benefits of the CHP facility making it more analogous to an oil-fired power plant in terms of the carbon intensity of the electricity produced. In other words, GHG emissions savings associated with beneficial biogas would have been quickly negated.

The survey empowered the City of Columbus to take significant steps to include mitigation abatement as part of the bioenergy project including replacing their existing floating covers, treating air with fugitive methane, and optimizing their digestion process to decrease residual methane release downstream.

These steps help mitigate 91% of identified emissions in the next five years, thus helping to achieve their climate action goals and reducing overall facilitywide emissions by 80% (not including fugitive nitrous oxide). This has allowed the City to secure federal funding and maximize the financial returns of their bioenergy program.

Bottom line

Consider whether fugitive methane emission may be an issue at your WRRF by asking these questions:

- Do you or are you planning to beneficially use biogas?

- Do you have digesters with floating covers?

- Do you and/or your utility have GHG emissions reduction goals or a climate action plan?

- Do you thicken, dewater, or store digested biosolids?

These factors increase the likelihood that your WRRF would benefit from a fugitive methane evaluation. Being proactive about fugitive methane can lead to multi-benefit results for your facility, community, and the environment both now and in the future.