Data science is transforming how the water industry designs, operates, and maintains infrastructure. This three-part advanced analytics blog series explores how BC helps our clients make the most of the data they are already collecting in SCADA, lab analysis, asset databases, and metering.

BC has partnered with Seeq, an advanced analytics software company, to effectively leverage and transform data into decisions for the water and wastewater industry. BC’s expertise combined with this powerful new tool enables water and wastewater utilities to:

- Use the data they are already collecting to make data-driven decisions based on the specific system conditions

- Identify opportunities to optimize existing systems and processes, and implement the analytics to achieve that optimization

- Detect small changes in data trends that signify larger issues, before they become problems

Check out this recorded webinar to learn more about how advanced analytics are transforming the water and wastewater industry.

Advanced analytics optimizes dynamic treatment dosing for cost savings

Treatment plant operators may have concerns when setting up automated systems that directly affect treatment outcomes. Regulatory permit limits, environmental protection, economic vitality, and, most importantly, public health are on the line with any process change. Operators are continuously faced with issues that require quick, informed decisions, with no room for error. Years of experience lead to systems and norms that allow operators to do their jobs, but may not result in optimized conditions and expenses.

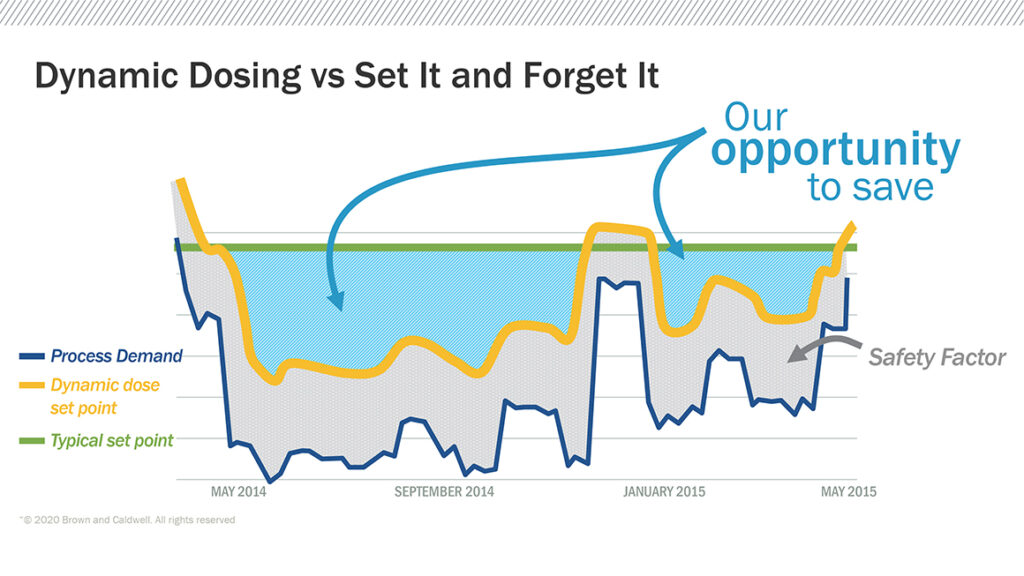

Chemical dosing is the perfect example of how operators choose a “set it and forget it” approach. By setting a constant chemical feed rate based on the highest demand conditions, one can be confident that the dosing will be high enough for all conditions. However, this approach also means that the dose is often higher than necessary.

Dynamic dosing, which varies with the actual chemical demand, can lead to significant cost savings with the same successful treatment outcome. When connected directly to a plant’s SCADA historian, BC engineers help clients use Seeq to develop sensor trust and data cleansing routines so that data from existing instrumentation can be used to identify trends and relationships that inform dynamic dosing.

Recently, BC and Seeq helped Utah’s largest wastewater reclamation facility, Central Valley (CVWRF), discover through diagnostic analytics that its secondary effluent bacteria concentration was highly correlated with seasonal temperature trends. The facility had been dosing at a constant rate all year using a level that was necessary for higher temperatures but not needed for cooler months. BC assisted CVWRF in using Seeq’s advanced analytics platform to identify an opportunity to optimize the treatment processes using real time UV transmittance and intensity sensors. This solution reduces UV power consumption by dynamically dosing to the seasonal fluctuations in water quality. Plant operators, who have ultimate control over the dosing, can easily see the dose recommended by the analytics and adjust the controls accordingly. The CVWRF general manager estimates that the plant will save up to $185,000 per year in disinfection costs after implementing the solution.

“Utilities can see significant savings by leveraging predictive analytics to assist operators.”

Brown and Caldwell’s National Analytics Engineering Lead Jamie Lefkowitz