Faced with high and low pH discharges, which contributed to corroding sewers and pump stations, the City of Memphis (City) needed an efficient digital solution to monitor discharge sampling across one of the nation’s largest industrial water pretreatment programs.

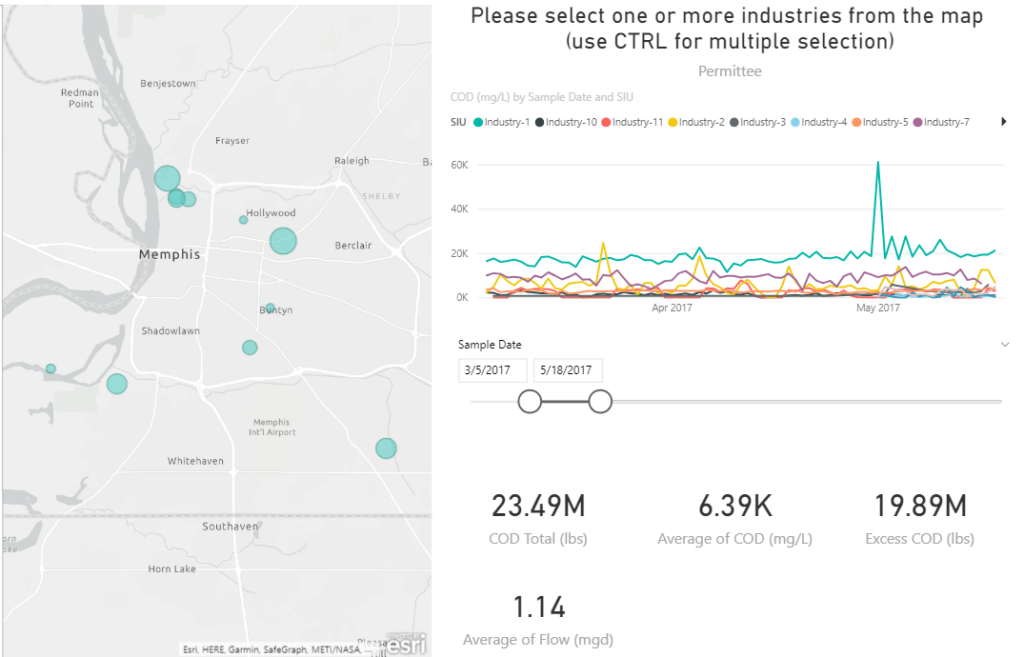

BC installed real-time spectrographic sensors at industrial discharge sites and the City’s two WWTPs to monitor pH, chemical oxygen demand (COD), and other water quality parameters. With a staff of 13 and more than 100 industrial sampling sites within the City’s wastewater service area, these inexpensive sensors were installed in remote locations to quickly understand what’s happening further upstream without relying on inspectors or self-reporting. A map-based dashboard displays sensor data, discharge parameters, alerts, and notifications, empowering City staff with the information to monitor what is being discharged into the sewer in real-time. To potentially avoid over or under treatment and to protect the integrity of their assets, this real-time data gives the City between two to six hours to adjust plant operations while ensuring proper billing and compliance.

BC also developed a corrosivity model to address high pH discharges and reviewed the magnitude of industrial COD discharges to support additional treatment charges that would allow the City to accommodate increased flows and loads.

“The fact that we can use Tech, use data and actually help improve our Department … that means a lot to me.”

Tasha King-Davis, Administrator of Environmental, Compliance and Permits, Memphis Division of Public Works