The federal government estimates that more than $384 billion in capital investment is needed by 2030 to maintain the nation’s drinking water infrastructure. Publicly owned wastewater utilities need about $270 billion during the same period.

Experts in this cash-strapped industry say that projects often take too long to complete and regularly suffer from cost overruns. Funding gaps, municipal politics, and environmental compliance are often the source of delays and difficulties. But some of the most entrenched inefficiencies arise in the infrastructure development business itself.

Navigating the design-bid-build method of project delivery can be a source of cost challenges and schedule problems for water and wastewater utilities. Just ask Steve Gates, senior vice president at Brown and Caldwell.

“With the design-bid-build process, there’s a higher potential for problems between the multiple contracting parties,” Gates said. “Accountability for project performance is diffused among multiple parties.” The result, he said, can be “disputes, delays and cost increases.”

“With the design-bid-build process, there’s a higher potential for problems between the multiple contracting parties,” Gates said. “Accountability for project performance is diffused among multiple parties.” The result, he said, can be “disputes, delays and cost increases.”

“But a growing number of water and wastewater utilities are trying another way,” Gates said, “contracting out key infrastructure projects to design-build firms, who can handle the effort from start to finish, instead of the once-traditional model of hiring a designer and taking the lowest-bidding contractor.”

“Historically, the owner would sit in one corner, the construction folks would sit in one corner, and the design folks would sit in one corner,” Gates said.

That’s a formula for disputes. “With design-build, by definition, people are collaborating. The real magic of design-build contracting is the broad efficiency gain that results from the collaboration inherent in the process,” he said.

The trend is paving the way for sophisticated utilities to streamline the lumbering process of infrastructure development. Gates said he sees an uptick in design-build contracting in the water and wastewater industry.

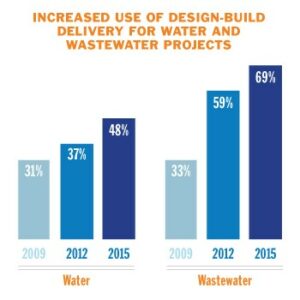

“Coming out of the Great Recession, we’re seeing a rapid acceleration in the design-build market. Our customers deferred projects that needed to be built. Owners are increasingly turning to design-build to make up for lost time,” he said. In fact, the Water Design-Build Council’s 2015 Annual Report shows that design-build delivery is selected for water projects 48 percent of the time, and 69 percent of the time for all wastewater projects.

Research from the Water Design-Build Council also shows that utility owners choose collaborative delivery methods primarily for the schedule efficiencies, cost advantages, pricing transparency, and ultimately, better quality results.

“Having the design-build process in the toolbox of project delivery options helps utilities do more with less, which in turn stabilizes rates. Design-build contracting promotes innovation, with a long-term benefit of improved performance at facilities,” Gates said.

When asked why Hampton Roads Sanitation District in Virginia Beach, Va., chose design-build, Bruce Husselbee, Director of Engineering, said “Our rates are increasing and a lot of it is driven by our capital program, so we’re getting more public scrutiny than ever. Ratepayers want to know that we’re spending their money wisely. More folks are asking questions, and it’s a matter of trust.

“Our capital program is a promise to our ratepayers that we will maintain our assets in a cost-effective manner, and deliver projects when needed. So with design-build delivery, we get projects done on time, we stay within budget, we have that trust with the project team, and things go well. All of these drivers have led us to look at design-build delivery.”

But for some, these collaborative delivery methods are still new, and there is much to learn.

At the Design-Build Institute of America’s recent water/wastewater conference, a number of owners were in attendance for the first time and were seeking out peers for their advice on how to more effectively approach their projects.

David Springer, Water Resources Plants Engineer for Greenville (N.C.) Utilities, was one of them. “I attended DBIA to learn more about the process, and several things are influencing our decision to use design-build. We want to build a project were we can continue to operate existing facilities unhindered and without impacts, and continue to meet our core directive, which is providing water to our customers, without violations, while we’re in the construction process.”

It’s clear that the market is seeing efficiency gains from design-build delivery, leading more and more owners to consider it as a viable option for their capital programs. Published research from the Water Design-Build Council and resources from the Design-Build Institute of America continue to educate industry professionals about how to maximize success with this method.

This series of articles and interviews about design-build will lay the foundation for a continuing dialogue on the latest strategies to help water and wastewater utilities meet the challenges ahead. We’ll explore the various collaborative delivery methods, profile utilities that have successfully implemented design-build as well as others that have determined it wasn’t right for them, and surface industry insights from around the country. We hope you’ll join this conversation and share your stories and best practices so that we can all benefit going forward.