From Proof to Proven:

Journeys to Water Independence

From proof to proven:

Journeys to Water Independence

Driving progress towards a secure water future through innovation, teamwork, and community solutions

With the State of California Department of Water Resources estimating a 10% reduction in water supply by 2040 due to climate change, utilities across California need to act now to move towards water self-sufficiency and become less reliant on imported water. The journey to water independence can be daunting, unclear, or downright muddy. From developing new resilient water supplies and increasing local water resources to investing in desalination and other technologies, utilities are considering: “What is the right path to water independence?”

“If we look at the big regional picture, states like California, Arizona, and Nevada are all supposed to be taking less water out of the Colorado River in the future. So, the fewer straws now, the closer we are to water resiliency.”

–Adam Zacheis, Regional Practice Leader for Water Reuse

Learn how three utilities are making their dream of water independence a reality

1st

The City of Santa Monica’s infrastructure investments increased the water supply 65%, and boosted plant efficiency more than 90%.

100%

The City of Los Angeles is making big strides with the full-scale Hyperion Advanced Water Treatment Facility proof-of-concept.

$50M

The City of Camarillo transformed unusable brackish groundwater into a local source of drinking water and increased recycled water for agriculture, saving significant costs over 20 years.

Meet the people who shaped the outcomes of these journeys

The dreams these utilities have achieved are no small feat. It takes courage to solve big challenges, innovate, and change the course of the future. Teamwork with the right blend of ingenuity and creativity paired with practical thinking leads to big breakthroughs. Community understanding and stakeholder input unlocks the best possible outcomes for generations to come. No two utilities capture and deliver water in the exact same way, and every project has a unique story of how they paved their own path to greater water independence.

Hyperion Advanced Water Purification Facility

Andrew Lazenby saw the limited urban space for the water treatment site not as a barrier, but as an opportunity to develop more efficient, sustainable, and creative solutions by leveraging the latest technology.

Flow Reversal Reverse Osmosis

Adam Zacheis conceptualized the flow reversal reverse osmosis process in the early stages of his career and applied similar RO (Reverse Osmosis) technology on Arcadia WTP decades later.

Tapping industry experts and bench-scale testing

Hisyam Mohsin and the Virginia Tech research team were committed to a creative yet disciplined way of using bench-scale testing to replicate the treatment process to ensure maximum safety before the City began distributing the desalinated water.

Dream Job

Fastrack your career: If you’re inspired and want to work with these teams on the next exciting project, check out these water recycling job oportunities.

Dream it, build it

Moving Los Angles one step closer to a more self-reliant water future with collaborative delivery. Whether you’re a project owner or contractor, work with a partner that helps you realize your vision.

Pipe dreams

From planning and building one of the world’s largest water recycling programs, you can make big dreams a reality. See how we’re helping Los Angeles achieve an abundant, sustainable, and accessible water future.

Private/Public Funding

Achieve your water independence goals through private/public funding resources. We work with private and municipal clients to reuse and replenish water, reducing water risks to operations and increasing freshwater availability. In most instances, these collaborations result in a positive, measurable impact on the community and watershed.

Hyperion Advanced Water Purification Facility

Andrew Lazenby saw the limited urban space for the water treatment site not as a barrier, but as an opportunity to develop more efficient, sustainable, and creative solutions by leveraging the latest technology.

Flow Reversal Reverse Osmosis

Adam Zacheis conceptualized the flow reversal reverse osmosis process in the early stages of his career and applied similar RO (Reverse Osmosis) technology on Arcadia WTP decades later.

Tapping industry experts and bench-scale testing

Hisyam Mohsin and the Virginia Tech research team were committed to a creative yet disciplined way of using bench-scale testing to replicate the treatment process to ensure maximum safety before the City began distributing the desalinated water.

Dream Job

Fastrack your career: If you’re inspired and want to work with these teams on the next exciting project, check out these water recycling job opportunities.

Dream it, build it

Moving Los Angles one step closer to a more self-reliant water future with collaborative delivery. Whether you’re a project owner or contractor, work with a partner that helps you realize your vision.

Pipe dreams

From planning and building one of the world’s largest water recycling programs, you can make big dreams a reality. See how we’re helping Los Angeles achieve an abundant, sustainable, and accessible water future.

Private/Public Funding

Achieve your water independence goals through private/public funding resources. We work with private and municipal clients to reuse and replenish water, reducing water risks to operations and increasing freshwater availability. In most instances, these collaborations result in a positive, measurable impact on the community and watershed.

Increased Water Supply with First U.S. FRRO Treatment Technology

Increased Water Supply with First

U.S. FRRO Treatment Technology

Arcadia Water Treatment Plant Expansion and Olympic Well Field Restoration

City of Santa Monica | Los Angeles County, CA

With the right team, anything is possible. Needing an immediate solution to reduce the City of Santa Monica’s reliance on imported water, develop sustainable water supplies, and increase groundwater production all during unprecedented working conditions in a pandemic; saying this was a challenging project is an understatement. With the odds stacked against them, the tenacious project team, including Walsh Construction, was committed to finding and delivering the best solution and innovate along the way. The finished $72 million Arcadia WTP expansion has increased treatment capacity with a novel high recovery reverse osmosis system, producing more finished drinking water with less waste being discharged to the sewer. A win-win for the City and the environment.

“It came down to the quantity of water that could be produced so the City didn’t have to buy as much imported water. We knew every extra percentage got the city closer to their goal.”

BC Senior Engineer

Chris Kindle

%

Increase in the City's Water Supply

%

Plant efficiency reached with Flow Reversal Reverse Osmosis (FFRO)

%

Less reverse osmosis concentrate discharged into the sewer

Milestone met, enabling the City to meet water independence goal

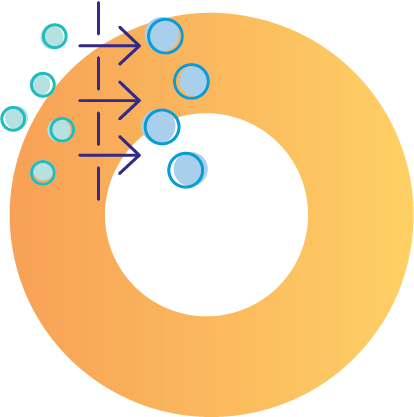

About FRRO Technology

The City enhanced its current reverse osmosis system by incorporating the innovative Flow Reversal Reverse Osmosis (FRRO) technology, a first of its kind in the United States. This innovation boosted production efficiency from 80% to 90% or higher, generating more high-quality drinking water using the same volume of raw groundwater and reducing overall groundwater demand.

INNOVATION

Pioneering FRRO pilot results leads to adoption

To get more treatment capacity, BC’s Project Manager, Adam Zacheis, led a team to pilot two technologies: Closed Circuit Reverse Osmosis (CCRO) and Flow Reversal Reverse Osmosis (FRRO), each was evaluated on: operations and maintenance; online time; membrane replacement; and chemical consumption. He developed the concept of FRRO for a small water district in Southern California early in his engineering career. The process has evolved since then into an emerging reverse osmosis technology. Although, technology alone isn’t enough, because it’s critical in any plant expansion to get adoption from the team that will operate and maintain the finished project. Seeing the real-time data analytics dashboard showing the percentages increase of each treatment technology led to the City choosing FRRO.

“Over the course of the FRRO piloting, less frequent cleaning was required compared to the CCRO system. This was a testament to the FRRO technology, which reverses flow and rotates blocks of pressure vessels before scaling can take hold and decreases treatment efficiency.”

—BC Project Manager and Innovator, Adam Zacheis

TEAMWORK

Trust and quick-thinking enables operational continuity

As the design-build process kicked off, there were times when troubleshooting required team members to be immediately on site. During startup there was an issue with the chemical feed pumps, and Senior Engineer, Chris Kindle, met with the City’s mechanical engineer to determine that there was another injection pump that was providing too much pressure into the chemical feed system. They made recommendations for throttling that pump back with different valving and different piping arrangements to get the system to operate without shutting down. “The fast pace and problem-solving aspects of my job are what I like most about working on design-build projects,” said Kindle.

“I was the electrical engineer for the first expansion of the Arcadia plant 15 years ago. After working on this second expansion, I realize how much trust I had built over the years. Working with friends and people you have known for years positively influenced the outcomes of this second plant expansion.”

—BC Senior Engineer

Chris Kindle

COMMUNITY

Providing a new water source and peace of mind

As a part of the Arcadia WTP expansion to increase treatment capacity, the team also designed and built the new Olympic Advanced Water Treatment Facility (AWTF) to add a drinking water source to the plant and to protect public health by cleaning up the contaminated Olympic Well Field groundwater. The AWTF uses an UV-AOP with hydrogen peroxide treatment process followed by granular activated carbon for hydrogen peroxide quenching to treat before blending the flow within the Arcadia WTP. The expansion provided an additional 3,200 AFY of groundwater and gives the future community peace of mind knowing they are one step closer to a sustainable water source.

“The ratepayers of Santa Monica should be proud. The City leaders knew if they leveraged innovative technology and their existing assets, they could maximize water recovery at Arcadia WTP and make the city more water independent.”

—BC Senior Engineer

Chris Kindle

IMPACT

The final leap towards 100% water self-sufficiency

The Arcadia WTP Expansion is the last major project for the City that gets them closer to their 100% water self-sufficiency goal. The new AWTF taps into their groundwater from their Olympic Well Field, no longer needing to worry about water quality due to industrial contamination. City leadership saw the need to be more sustainable 30 years ago, and with these upgrades they are now at the forefront of deploying sustainable water infrastructure projects in Southern California.

“Santa Monica is innovative and always looking to the future. They are not stopping at this advanced water treatment facility. In fact, they are on the fast track to be one of the first DPR (Direct Potable Reuse) and hope to tie in all their facilities to provide as much reuse and self-sufficiency in the City as possible.”

—Design Manager, Kirstin Kale

Meet the people who shaped the outcomes of these journeys

The dreams these utilities have achieved are no small feat. It takes courage to solve big challenges, innovate, and change the course of the future. Teamwork with the right blend of ingenuity and creativity paired with practical thinking leads to big breakthroughs. Community understanding and stakeholder input unlocks the best possible outcomes for generations to come. No two utilities capture and deliver water in the exact same way, and every project has a unique story of how they paved their own path to greater water independence.

Hyperion Advanced Water Purification Facility

Andrew Lazenby saw the limited urban space for the water treatment site not as a barrier, but as an opportunity to develop more efficient, sustainable, and creative solutions by leveraging the latest technology.

Flow Reversal Reverse Osmosis

Adam Zacheis conceptualized the flow reversal reverse osmosis process in the early stages of his career and applied similar RO (Reverse Osmosis) technology on Arcadia WTP decades later.

Tapping industry experts and bench-scale testing

Hisyam Mohsin and the Virginia Tech research team were committed to a creative yet disciplined way of using bench-scale testing to replicate the treatment process to ensure maximum safety before the City began distributing the desalinated water.

Dream Job

Fastrack your career: If you’re inspired and want to work with these teams on the next exciting project, check out these water recycling job oportunities.

Dream it, build it

Moving Los Angles one step closer to a more self-reliant water future with collaborative delivery. Whether you’re a project owner or contractor, work with a partner that helps you realize your vision.

Pipe dreams

From planning and building one of the world’s largest water recycling programs, you can make big dreams a reality. See how we’re helping Los Angeles achieve an abundant, sustainable, and accessible water future.

Private/Public Funding

Achieve your water independence goals through private/public funding resources. We work with private and municipal clients to reuse and replenish water, reducing water risks to operations and increasing freshwater availability. In most instances, these collaborations result in a positive, measurable impact on the community and watershed.

Hyperion Advanced Water Purification Facility

Andrew Lazenby saw the limited urban space for the water treatment site not as a barrier, but as an opportunity to develop more efficient, sustainable, and creative solutions by leveraging the latest technology.

Flow Reversal Reverse Osmosis

Adam Zacheis conceptualized the flow reversal reverse osmosis process in the early stages of his career and applied similar RO (Reverse Osmosis) technology on Arcadia WTP decades later.

Tapping industry experts and bench-scale testing

Hisyam Mohsin and the Virginia Tech research team were committed to a creative yet disciplined way of using bench-scale testing to replicate the treatment process to ensure maximum safety before the City began distributing the desalinated water.

Dream Job

Fastrack your career: If you’re inspired and want to work with these teams on the next exciting project, check out these water recycling job opportunities.

Dream it, build it

Moving Los Angles one step closer to a more self-reliant water future with collaborative delivery. Whether you’re a project owner or contractor, work with a partner that helps you realize your vision.

Pipe dreams

From planning and building one of the world’s largest water recycling programs, you can make big dreams a reality. See how we’re helping Los Angeles achieve an abundant, sustainable, and accessible water future.

Private/Public Funding

Achieve your water independence goals through private/public funding resources. We work with private and municipal clients to reuse and replenish water, reducing water risks to operations and increasing freshwater availability. In most instances, these collaborations result in a positive, measurable impact on the community and watershed.

The keystone for a 100% water recycling future

The keystone for a 100% water recycling future

Hyperion Water Reclamation Plant Advanced Water Purification Facility Progressive Design-Build

City of Los Angeles / LA Sanitation & Environment (LASAN) | Playa Del Rey, CA

The Hyperion Advanced Water Purification Facility (Hyperion AWPF) is more than a water treatment facility, it’s a symbol of the City of Los Angeles’ dedication to water security, a sustainable future, environmental protection, and public education about resource conservation.

The new facility will treat primary effluent from the Hyperion Water Reclamation Plant (HWRP) to produce a high-quality, advanced treated recycled water for various uses at the Los Angeles International Airport (LAX), including cooling tower make-up water, toilet flushing, irrigation, and other non-potable uses. The recycled water will also be used at HWRP to offset potable water demands in its industrial water system, as well as provide recycled water to existing internal infrastructure.

Often mistaken as a pilot project, the full-scale 1.5-mgd Hyperion AWPF project serves as a “proof of concept” towards the City’s ambitious goal of recycling 100% of LA’s wastewater at one of the largest water reclamation plants in the United States, the HWRP. The facility encompasses innovative solutions to address the challenges of urban water management, setting a precedent for cities worldwide.

“The water supply that we relied on for the last 100 years has changed. Due to climate change, the abundance of water and its frequency has transformed. We are no longer able to rely on what has worked in the past, so we must create our own future water supply.”

BC Vice President,

Steve Hirai

Hours for the Hyperion AWPF total treatment process at full capacity from primary effluent to proof-of concept, reuse ready

%

Reduced space for the Hyperion AWPF was not a barrier, but fueled more efficient, accessible, and creative solutions for the client

In savings through value engineering options and concepts with progressive-design build delivery method

Anticipation to turn on the Hyperion AWPF to pump recycled water to LAX for toilet flushing, cooling towers, and more

Innovative design at the Hyperion Advanced Water Purification Facility

With 30% less space to work within than originally planned, the BC team needed to get creative in fitting all the necessary equipment for the treatment process. We spent significant time listening and incorporating preferences from the operations and engineering staff, making the facility more efficient and user-friendly in the day-to-day. The innovative components include:

- Treatment process equipment location

- Operating equipment accessibility

- Post-treatment technology

- MBR basins depth

- Advanced Treatment Building design

INNOVATION

Transforming constraints into opportunities

Hyperion AWPF’s design incorporates advanced treatment processes, including membrane bioreactors (MBR), reverse osmosis (RO), and ultraviolet advanced oxidation (UV-AOP), however, what sets it apart is the scale of AWPF’s operations and its integration within the existing infrastructure.

Innovation was achieved through how we applied and fit the technology within the site constraints; and how we designed some of the ancillary areas specific to the City’s project needs, preferences, and their vision.

The Hyperion AWPF informs future planning and design decisions that will help reduce cost, save time, and give the City/LASAN the confidence in operational decisions that they make. The treatment process may evolve in the future Hyperion facility investment, but the Hyperion AWPF gives LASAN staff a unique opportunity to enhance operational experience with advanced treatment technologies.

“Every site has unique challenges, but it’s the Hyperion Advanced Water Purification Facility constraints that spurred innovation. When we found out that we had 30% less space to work with, we saw limitations of space not as a barrier, but an opportunity to develop more efficient, sustainable, and creative solutions that maintain Los Angeles Sanitation & Environment (LASAN’s) vision.”

—BC Senior Principal and Environmental Engineer,

Linda Sawyer

TEAMWORK

Upfront collaboration for accelerated project execution

This was LASAN’s first progressive design-build (PDB) delivery project, bringing a level of collaboration with LASAN and contractor partner, Walsh Construction, early in the project through the 70% design phase. This provided LASAN the opportunity to give their input, help with decisions, and incorporate their preferences into the design so that by the time the design was finished, and construction had started, there were no surprises.

The team facilitated workshops and collaborated directly with plant management, engineering, and operations staff, resulting in better accessibility to equipment. The team was able to vet multiple ideas with Walsh Construction, which was valuable as they helped confirm constructability in the workshops. Finally, the team conducted manufacturer preselection for major process equipment to help inform and streamline the remaining design process—ultimately landing on what has been designed and built.

“Using the PDB delivery method allowed the City to be involved all the way through, giving them the ability to make key decisions so there weren’t any surprises. LASAN’s input and operations preferences were incorporated into the design and our collaborative workshop approach provided insights into advanced treatment process options and equipment preselection.”

—BC Senior Director and Project Manager, Andrew Lazenby

COMMUNITY

Designed to connect with the public, next generation

The original concept design for the Hyperion AWPF planned to integrate a warehouse-type enclosure, but the vision for the building evolved into a one-of-a-kind visitor-friendly facility. The team worked closely with the architect, David Crawford, to develop aesthetic and educational features, including a multi-purpose facility to enclose and protect the advanced treatment processes, an outdoor gathering area, and a planned water feature. BC also designed educational signage throughout the facility for tours, which will help educate the general public, students, and professionals on the benefits of the City’s future plans for the HWRP. Signage installation will commence soon.

With the AWPF building now complete, tour groups see a roof structure reminiscent of an ocean wave along with an open, bright interior that showcases the RO and UV-AOP, and a fully accessible terrace deck overlooking the Pacific Ocean and the future Hyperion concept.

“The building is all inclusive, multi-purpose and we are all proud of its evolution,” Andrew said, “The City invested in the building with a vision to configure it for tours, and it is now paying dividends with hosting tour groups. Educating the public, our next generation of leaders and attracting more people to our water/wastewater industry—it’s important to connect with the community and help promote the importance of a One Water future.”

—BC Senior Director and Project Manager, Andrew Lazenby

IMPACT

Turning wastewater into a water supply

The City is looking forward rather than being reactive. The Hyperion AWPF is setting up the future of converting the HWRP capacity for reuse, with the intent of every drop of purified water produced at the AWPF replacing an equivalent drop of potable water that needs to be imported.

The Hyperion AWPF is a small, but mighty link to the City’s multi-billion dollar future investment. The technologies may evolve in the future, but the AWPF provides operators the chance to learn and optimize how to efficiently integrate advanced treatment at the HWRP. It will inform future design decisions that will benefit the environment, water supply, and provide an opportunity for community education and workforce engagement.

“Ultimately, it’s proving that we could recycle all the wastewater Los Angeles is producing to use it as a water supply with the goal of recycling 100% of the water that we’ve already imported and used and putting it back into our water cycle.”

—BC Vice President, Steve Hirai

Meet the people who shaped the outcomes of these journeys

The dreams these utilities have achieved are no small feat. It takes courage to solve big challenges, innovate, and change the course of the future. Teamwork with the right blend of ingenuity and creativity paired with practical thinking leads to big breakthroughs. Community understanding and stakeholder input unlocks the best possible outcomes for generations to come. No two utilities capture and deliver water in the exact same way, and every project has a unique story of how they paved their own path to greater water independence.

Hyperion Advanced Water Purification Facility

Andrew Lazenby saw the limited urban space for the water treatment site not as a barrier, but as an opportunity to develop more efficient, sustainable, and creative solutions by leveraging the latest technology.

Flow Reversal Reverse Osmosis

Adam Zacheis conceptualized the flow reversal reverse osmosis process in the early stages of his career and applied similar RO (Reverse Osmosis) technology on Arcadia WTP decades later.

Tapping industry experts and bench-scale testing

Hisyam Mohsin and the Virginia Tech research team were committed to a creative yet disciplined way of using bench-scale testing to replicate the treatment process to ensure maximum safety before the City began distributing the desalinated water.

Dream Job

Fastrack your career: If you’re inspired and want to work with these teams on the next exciting project, check out these water recycling job oportunities.

Dream it, build it

Moving Los Angles one step closer to a more self-reliant water future with collaborative delivery. Whether you’re a project owner or contractor, work with a partner that helps you realize your vision.

Pipe dreams

From planning and building one of the world’s largest water recycling programs, you can make big dreams a reality. See how we’re helping Los Angeles achieve an abundant, sustainable, and accessible water future.

Private/Public Funding

Achieve your water independence goals through private/public funding resources. We work with private and municipal clients to reuse and replenish water, reducing water risks to operations and increasing freshwater availability. In most instances, these collaborations result in a positive, measurable impact on the community and watershed.

Hyperion Advanced Water Purification Facility

Andrew Lazenby saw the limited urban space for the water treatment site not as a barrier, but as an opportunity to develop more efficient, sustainable, and creative solutions by leveraging the latest technology.

Flow Reversal Reverse Osmosis

Adam Zacheis conceptualized the flow reversal reverse osmosis process in the early stages of his career and applied similar RO (Reverse Osmosis) technology on Arcadia WTP decades later.

Tapping industry experts and bench-scale testing

Hisyam Mohsin and the Virginia Tech research team were committed to a creative yet disciplined way of using bench-scale testing to replicate the treatment process to ensure maximum safety before the City began distributing the desalinated water.

Dream Job

Fastrack your career: If you’re inspired and want to work with these teams on the next exciting project, check out these water recycling job opportunities.

Dream it, build it

Moving Los Angles one step closer to a more self-reliant water future with collaborative delivery. Whether you’re a project owner or contractor, work with a partner that helps you realize your vision.

Pipe dreams

From planning and building one of the world’s largest water recycling programs, you can make big dreams a reality. See how we’re helping Los Angeles achieve an abundant, sustainable, and accessible water future.

Private/Public Funding

Achieve your water independence goals through private/public funding resources. We work with private and municipal clients to reuse and replenish water, reducing water risks to operations and increasing freshwater availability. In most instances, these collaborations result in a positive, measurable impact on the community and watershed.

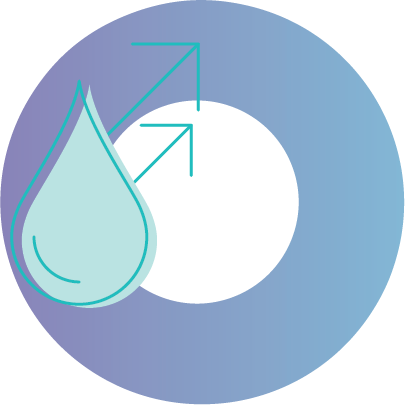

Transformed groundwater resources leads to new local water supply

Transformed groundwater resources leads to new local water supply

North Pleasant Valley Groundwater Desalter Facility

City of Camarillo | Ventura County, CA

The North Pleasant Valley Groundwater Desalter Facility is a 4-mgd greenfield plant that treats brackish groundwater into a reliable source of high-quality drinking water, creating an entirely new local water supply and maximizing the local groundwater resources. The $67 million project, which won a national award, supports California’s Water Supply Strategy to expand brackish desalination, driven by innovative desalination technologies that make using brackish groundwater for potable water supply more feasible and cost-effective.

“This project secures Camarillo’s water future with a cost-effective and eco-sustainable way of reusing and reclaiming groundwater. I was proud to see the more than 100 contributors to the project at the ribbon-cutting ceremony. Standing there and seeing everyone who made it happen, really put it in perspective for me.”

%

Increase in new local water supply portfolio in addition to the City’s existing groundwater allocation

%

City’s water supply is now sourced from local groundwater and cutting the need for imported water in half

Million tons of salt removed every year from the watershed

Expected savings over 20 years from buying less imported water.

Tapping industry experts and bench-scale testing

To comply with regulatory expectations to protect public safety prior to distributing treated water, the City conducted several phases of testing, including desktop studies, modeling, bench-scale testing, and plant commissioning with significant sampling. Once the California State Water Resources Control Board Division of Drinking Water approved the desalter to deliver treated water to customers, the City implemented a phased, increasing-flow approach, along with rigorous water quality sampling and monitoring, to introduce the treated water to the distribution system. BC collaborated with the Virginia Tech research laboratory to conduct extensive corrosion control and bench-scale testing involving small pipe samples taken from the City’s distribution system to replicate system water quality and pipe material compatibility on a smaller scale. Instead of running the traditionally recommended pipe-loop test, the team used the more affordable, streamlined coupon-testing method to assess corrosion. The City, engineering team, and regulators concluded that a follow-up pipe loop test was not warranted based on the observations and results of their existing aged-pipe testing.

BC has its own treatability testing laboratory that does bench- and pilot-scale testing in-house to inform practical approaches and solutions. Watch the video to learn more.

INNOVATION

Solving complex treatment, remaining compliant with bench-scale testing

The project aimed to transform unusable brackish groundwater into a high-quality, affordable water source while removing damaging salts and other constituents from the regional watershed. To comply with water quality regulations and public safety, the City implemented a path that required innovative solutions and collaboration. Lessons learned from the Flint, Michigan water crisis highlighted the importance of addressing pipe corrosion with the introduction of new or alternate water supplies, prompting extensive testing.

BC tapped Dr. Marc Edwards and his team from Virginia Tech, known for their expertise in bench-scale testing and understanding of metal leaching and corrosion, to support the project. They conducted a 12-week bench-scale test with pipe coupons from the City’s service area. This bench-testing work aimed to evaluate the corrosivity of this new water blend on the City’s plumbing. Their contribution played a key role in the refinement of the desalter treatment approach and operations.

“The learning moment was during bench-scale testing when the samples came back as ‘unexciting.’ Having that peace of mind—knowing the results showed that the metals leaching is comparable to the current water when we introduced the new treated water—meant everything to us.”

—BC Senior Staff Environmental Engineer, Hisyam Mohsin

TEAMWORK

Meeting tight schedules and overcoming design hurdles as a team

Early in design, the City pivoted from the original site location, creating design challenges for the new stormwater, catch basin, and conveyance system. BC worked collaboratively with City staff to find solutions and make quick decisions to keep the project on track. The salt removed from the groundwater through reverse osmosis (known as concentrate) could not be discharged to inland waterways like rivers or creeks, so the City coordinated with the Calleguas Municipal Water District to connect to their Salinity Management Pipeline. This pipeline safely conveys concentrate from the desalter to the Pacific Ocean via the outfall in Port Hueneme. The desalter is uniquely located adjacent to the Salinity Management Pipeline, thereby avoiding significant capital expenditure for connection to this critical regional infrastructure.

“Being able to serve our client in developing their first greenfield drinking water treatment plant offered a unique and challenging experience for our team. My approach when I manage any project is to make sure the team stays connected and sees the bigger picture. And they did. Even with a challenging schedule everyone took on a high-level of ownership to meet it. We knew this project was important to the City, so it was important to us.”

—BC Senior Director and Project Manager, Andrew Lazenby

COMMUNITY

Community input shapes facility, reflects values

Community involvement and input impacted the facility’s aesthetics, including keeping the mission-style architecture common in the area. The facility includes an administration and operations building configured to allow the City to seek future LEED certification, reflecting a commitment to environmental responsibility. The community requested an education center to be incorporated into the design, so students and the public can attend guided tours to learn about the water treatment process. With the community’s involvement during design, the finished project reflects the values of the community, while enhancing local water supply security and reducing dependence on imported water. The project embodies the community’s values through its drought resilience and environmental benefits, such as conserving water and removing damaging salts from the regional watershed, contributing to a sustainable future for Camarillo.

“We gave a presentation to educate students on the history of the project, the treatment process, and on how projects develop from design to construction. It was a terrific way to educate the upcoming generation on potential career paths in the water industry.”

—BC Design Manager, Kirstin Kale

IMPACT

From brackish to drinkable and much more

With the project’s completion, the City achieved its goal of transforming unusable brackish groundwater into a local source of high quality, affordable drinking water. They are protecting the Pleasant Valley Groundwater Basin from further migration of the brackish groundwater plume, while reducing salts and other constituents into their water supply. This project improves the water quality of recycled water produced at the City’s Water Reclamation Facility, because there are less salts in the potable water used by the community, and increases recycled water use to benefit the local agricultural municipal users. Through reducing the amount of water imported from the Colorado River and the Sacramento-San Joaquin Delta, this project provides environmental and supply benefits to all of California.

“Months after the plant was running at full capacity, we heard directly and indirectly from City staff and customers, ‘It’s great tasting water!’ If that is not a stamp of approval, then I don’t know what is.”

—BC Senior Director and Project Manager, Andrew Lazenby

Meet the people who shaped the outcomes of these journeys

The dreams these utilities have achieved are no small feat. It takes courage to solve big challenges, innovate, and change the course of the future. Teamwork with the right blend of ingenuity and creativity paired with practical thinking leads to big breakthroughs. Community understanding and stakeholder input unlocks the best possible outcomes for generations to come. No two utilities capture and deliver water in the exact same way, and every project has a unique story of how they paved their own path to greater water independence.

Hyperion Advanced Water Purification Facility

Andrew Lazenby saw the limited urban space for the water treatment site not as a barrier, but as an opportunity to develop more efficient, sustainable, and creative solutions by leveraging the latest technology.

Flow Reversal Reverse Osmosis

Adam Zacheis conceptualized the flow reversal reverse osmosis process in the early stages of his career and applied similar RO (Reverse Osmosis) technology on Arcadia WTP decades later.

Tapping industry experts and bench-scale testing

Hisyam Mohsin and the Virginia Tech research team were committed to a creative yet disciplined way of using bench-scale testing to replicate the treatment process to ensure maximum safety before the City began distributing the desalinated water.

Dream Job

Fastrack your career: If you’re inspired and want to work with these teams on the next exciting project, check out these water recycling job oportunities.

Dream it, build it

Moving Los Angles one step closer to a more self-reliant water future with collaborative delivery. Whether you’re a project owner or contractor, work with a partner that helps you realize your vision.

Pipe dreams

From planning and building one of the world’s largest water recycling programs, you can make big dreams a reality. See how we’re helping Los Angeles achieve an abundant, sustainable, and accessible water future.

Private/Public Funding

Achieve your water independence goals through private/public funding resources. We work with private and municipal clients to reuse and replenish water, reducing water risks to operations and increasing freshwater availability. In most instances, these collaborations result in a positive, measurable impact on the community and watershed.

Hyperion Advanced Water Purification Facility

Andrew Lazenby saw the limited urban space for the water treatment site not as a barrier, but as an opportunity to develop more efficient, sustainable, and creative solutions by leveraging the latest technology.

Flow Reversal Reverse Osmosis

Adam Zacheis conceptualized the flow reversal reverse osmosis process in the early stages of his career and applied similar RO (Reverse Osmosis) technology on Arcadia WTP decades later.

Tapping industry experts and bench-scale testing

Hisyam Mohsin and the Virginia Tech research team were committed to a creative yet disciplined way of using bench-scale testing to replicate the treatment process to ensure maximum safety before the City began distributing the desalinated water.

Dream Job

Fastrack your career: If you’re inspired and want to work with these teams on the next exciting project, check out these water recycling job opportunities.

Dream it, build it

Moving Los Angles one step closer to a more self-reliant water future with collaborative delivery. Whether you’re a project owner or contractor, work with a partner that helps you realize your vision.

Pipe dreams

From planning and building one of the world’s largest water recycling programs, you can make big dreams a reality. See how we’re helping Los Angeles achieve an abundant, sustainable, and accessible water future.

Private/Public Funding

Achieve your water independence goals through private/public funding resources. We work with private and municipal clients to reuse and replenish water, reducing water risks to operations and increasing freshwater availability. In most instances, these collaborations result in a positive, measurable impact on the community and watershed.